Tramex Concrete Moisture Meters Review

I imagine most people see concrete slabs and don’t give them any thought. On the surface, no pun intended, they seem relatively straight forward. Concrete is mixed and poured and a day later it is hard and you put a house on top of it. Anyone who deals with concrete understands there is a lot more going on. As the title would allude to, this post will cover different testing procedures to ensure concrete is sufficiently cured before installation of a flooring system. This is done to reduce the failure of the flooring system (i.e. delamination, blistering, peeling, staining or sweating). While the surface of a new concrete slab can appear to be dry, knowledge of the moisture content in the core of slab is not easily attained without specific equipment.

Surface Testing:

The simplest and most economical way of testing concrete floors for moisture is using a handheld meter than can take non-destructive surface moisture measurements. The Tramex CME4 Concrete Encounter is a standard analog moisture meter that is designed specifically for this purpose. The Tramex CME4 is calibrated specifically for concrete and measures moisture up to 6% and meets the ASTM F2659 standards for non-destructive operation. The meter has 8 spring loaded pins to ensure contact on an uneven surface.

CME4 Front and Back view

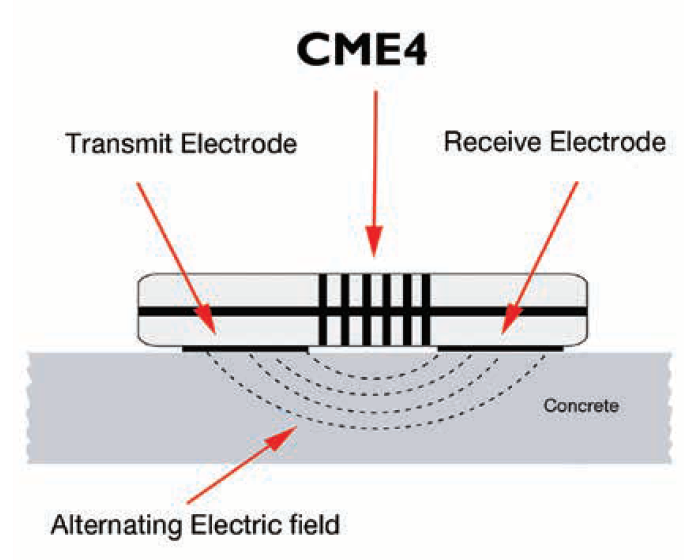

Non-destructive test measurements are done by sending an electric current into the concrete from the transmitting pins that penetrate up to ¾” into the surface of the concrete. The receiving electrodes complete the circuit and the detected strength of the current can be converted in a moisture content value. The strength of the signal varies with the amount of moisture in the concrete.

Graphical representation of non-destructive test procedure

Tramex also makes the CMEX II Concrete Moisture Meter which has the same features of the CME4 but has a digital display. It measures concrete moisture up to 6.9% and has ports to plug in probes for testing wood from 7-40% and for in-situ testing of concrete which we will cover next.

CMEX II Front and Back View

In situ testing:

When a surface measurement isn’t enough and the need to know more about the moisture content inside of a slab there is in situ testing. This type of testing is done to ensure the proper amount of moisture is present inside of the concrete slab before installation of flooring on top of the concrete. If too much moisture is still present this can lead to costly damage to any installed flooring. In situ testing solves this dilemma by giving a more accurate representation on the relative humidity level inside of the concrete slab. This method is done by drilling a hole roughly 40% depth of the concrete slab and placing a relative humidity probe into the hole and plugging the top. This allows the probe to read the relative humidity in the center of the slab which gives a much clearer representation of the humidity content inside the concrete slab. Usually these probes are left for a minimum of 24 hours after placement so the moisture can reach an equilibrium state and give a more accurate reading. Tramex CMEX II has ports that can accept their Hygro-I probe used for in situ testing. These probes meet ASTM F2170 standards and are reusable.

In-Situ Testing Probes for Tramex CMEX II

Concrete Moisture Kits:

Tramex offers three different Concrete Inspection Kits that can be described as Good, Better, Best. Each kit offers the same products as the previous kit but adds new products or increases the quantity of existing products. Here is a brief description and a picture showing what each kit offers.

Tramex CZK5.1 Concrete Inspection EZ Kit

The first kit is the Tramex CZK5.1 Concrete Inspection EZ Kit. This is the basic CMEX II Kit and offers the following.

- CMEX II – Concrete Moisture Meter

- 3 x Hygro-I Probes

- 12 x Hole Liners

- Easy Travel Case

Tramex CIK5.1 Concrete Inspection Kit

The second kit is the Tramex CIK5.1 Concrete Inspection Kit. This kit gives you an extra probe as well as an infrared thermometer and a calibration check salt.

- CMEX II – Concrete Moisture Meter

- 4 x Hygro-I Probes

- 12 x Hole Liners

- 1 x SAL75 (Calibration Check Salts)

- Infrared Thermometer

- Heavy Duty Carrying Case

Tramex CMK5.1 Concrete Inspection Master Kit

The third and final kit is the Tramex CMK5.1 Inspection Master Kit. This kit doesn’t add anything new from the previous kit but adds more in situ probes and two more calibration check salts.

- CMEX II – Concrete Moisture Meter

- 12 x Hygro-I Probes

- 25 x Hole Liners

- 3 x SAL75 (Calibration Check Salts)

- Infrared Thermometer

- Heavy Duty Carrying Case

Concrete moisture is more in depth than one would first expect. Depending on the level of accuracy you need there are different tests you can perform. This knowledge will guide you to which type of concrete moisture meter you will need. For simple surface measurements, a non-destructive meter such as the Tramex CME4 would suffice. If you are unsure if you will need to do in situ testing at some point you will want a meter that can do both surface measurements and in situ testing like the Tramex CMEX II. Hopefully you found this entry informative and helpful in selecting the proper concrete moisture meter. As a side note, if you have the need to test the moisture in other building materials you can check out the Tramex MEP Moisture Encounter Plus.

For more information and great pricing on Tramex and their line of moisture detection meters, follow this link.

Add new comment